Lab High Speed Disperser

- Lab High Speed Disperser is Suitable for Paint, Pigment, Dyestuff, Coating Printing Ink, for mixing, Dispersing, grinding

- Best use of Disperser is to dissolve and disperseion of Liquid and Liquid with solids.

- Disperser is availabe in Manual or Hydraulic Up and Down Arrangment.

- High Speed Dispersion machine has Starting Capacity Ranging from 50 litrer to 1000 liters

- Suitable for Putty, Primers, Distempers, Plastic paint, Exterior emulsions & premium wall finishes for Paint, Pigment, Dyestuff, Coating Printing Ink, for mixing, Dispersing, grinding.

The hand-lifting frequency conversion dispersing machine is a new type of product designed according to actual needs. It is mainly used in the pilot test of the production of various paints, coatings, pigments, plastics, food and other liquid slurries. Provide correct data for large-scale production, can also be used for small batch production, the equipment can be dispersed 5L-50L

working principle:

The sawtooth circular dispersing disc of the dispersing machine is dispersed in the container at high speed to complete the process of solid-liquid dispersion, wetting, depolymerization and stabilization. The slurry is rolled into a five-goat flow, which generates a strong vortex. The particles on the surface of the slurry drop spirally to the bottom of the vortex. A turbulent zone is formed at the edge of the dispersion disk at 2.5-5 mm. The slurry and particles are strongly sheared and impacted. With two beams, the slurry is fully circulated and turned over. The disperser has a laminar flow under the dispersion plate. The slurry layers of different flow rates diffuse with each other to play a dispersion role.

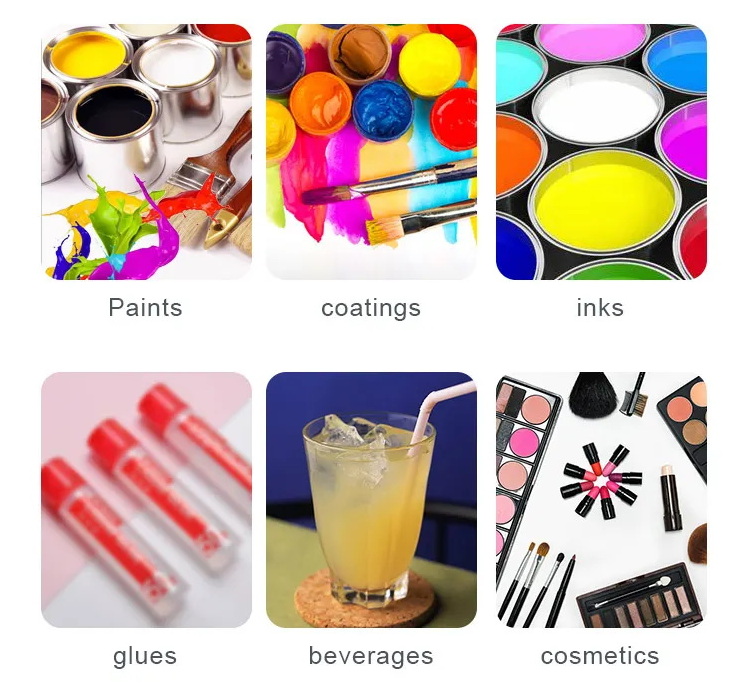

Scope Of Application

Lab High speed disperser applies to all kinds of liquid to premix, disperse, dissolve or color match etc. When it is mixing and dispersing, there is little air suction which can dissolve materials quickly and make the particle more smaller. It is widely used in coating, oil paint, ink, resin, papermaking, adhesive, medicine, pigment, color paste, food, beverage etc. to mix, disperse and dissolve two or more kinds of liquids and solid powders.

Lab High speed disperser applies to all kinds of liquid to premix, disperse, dissolve or color match etc. When it is mixing and dispersing, there is little air suction which can dissolve materials quickly and make the particle more smaller. It is widely used in coating, oil paint, ink, resin, papermaking, adhesive, medicine, pigment, color paste, food, beverage etc. to mix, disperse and dissolve two or more kinds of liquids and solid powders.

Application areas:

- Material viscosity: 25000cps

- Production capacity: 5L-50L

- Application areas: suitable for the dispersion and mixing of products in industries such as biology, medicine, food, paint, ink, adhesives, dyes, pesticides, etc.

- Applicable materials: various slurries with material viscosity below 25000cps and solid content below 60%: such as latex paints, industrial paints, water-based inks, pesticides, adhesives and more than a thousand kinds of materials.

Description

Product Specification

| Motor | 1HP / 2HP Compact AC Motor |

| Power Supply | Three / Single phase, 110V/220V, 50/60Hz |

| Mixing Impeller |

|

| Speed | Electronic variable speed inverter 0-6000 rpm |

| Material | SS 316L wetted parts |

| Mixing Capacity | 1 – 30 liter (H2O) |

| Lifting | by manual gas spring slider |

High Speed Disperser, High Speed Disperser mixer, Dissolver, Paint High Speed Disperser, dispersion machine

Ribbon Blender / Pug Mixer | Sigma Kneader | Twin Shaft Disperser

High Speed Disperser |

Ball Mill |

Process Reactors |

Disperser manufacturer

Homoginizer - emulsifier

| Twin Shaft Disperser manufacturering Company

Products

- Softgel Capsule Manufacturing Equipments

- Gelatin Cooking Mixer Manufacturer

- Gelatin Holding Tank

- Reaction Vessel

- V Cone Blender Mixer

- Condenser / Heat Exchanger

- Pressure Vessels

- Distillation Unit

- Pilot Reaction Unit

- Sigma Mixer

- Ribbon Blender

- ETO Sterilizer Machine

- Ethylene Oxide Sterilizer

- ETO Sterilizer for Hospital

- Sigma Mixer Kneader

- Jacketed Reaction Vessel

- Cylindrical Autoclave

- Sigma Kneader Mixer

- Reaction Vessel Exporter in India

- sigma mixer manufacturer

- Drum Flaker