Polyester Resin Reactor

Polyester resins are unsaturated resins formed by the reaction of dibasic organic acids and polyhydric alcohols are typically used in restaurants, kitchens, restrooms and other areas that require washable low-maintenance walls. We offer our clients a wide range of Polyester Resin reactor. We maintain high standards in our range of products. To maintain these international quality standards, we regularly keep a stringent check on the quality of the products at varied manufacturing stages. Polyester resins are used in sheet molding compound, bulk molding compound and the toner of laser printers. Wall panels fabricated from polyester resins reinforced with fiberglass.

(Saturated Polyester Resin Plant – Powder form)

(Saturated Polyester Resin Plant – Powder form)

(Polyester Resin Plant – Liquid form)

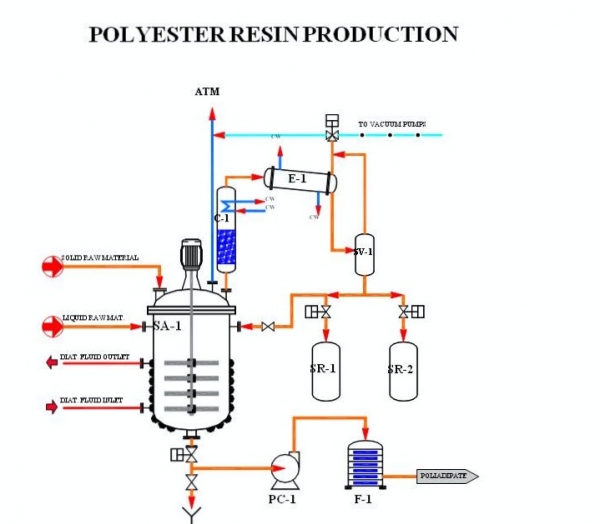

The major operations involved in the manufacture of polyester resin are esterfication and blending – which are carried in their respective kettles. The most common raw materials used are polypropylene glycol, melic anhydride and styrene monomer. In addition small quantities of inhibitors and other additives are required for the process. The process involved is poly condensation reaction and blending the polyester resin with the monomer. Due to the sensitivity of polyester resin to contamination; in the course of condensation reaction and during subsequent handling the material of construction must be carefully selected.

The esterfication reactor is changed through a manhole with required amount of glycol and the solid anhydride. The mass is heated up to 200°C under agitation and inert gas N2 is slowly applied. The partial condenser condenses the glycol but process the water to the total condenser. The esterification is continued until a predetermined acid value 10 to 15 is reached. After achieving the predetermined viscosity the heating is stopped and the batch is dropped in to the blending kettle. In the blending kettle the batch is cooled to 100 – 102°. Styrene is pumped in the blender and viscosity is adjusted until the batch attains room temperature. The batch is then pumped through filter in to the storage tanks.

*Model selection reference of Reaction Kettle

| Composition | Instructions |

| Specification (L) | 50-50000 |

| Design Pressure (Mpa) | Atmospheric Pressure or under pressure |

| Material | Carbon steel, stainless steel, enamel, graphite |

| Heating Forms | Electrical heating with medium in jacket, external half coil steam heating, external half conduction oil heating, hot water infrared heating etc. |

| Cooling Forms | Refrigeration medium in the internal pipe jacket |

| Blending Power | Model selection is made according to material viscosity, liquid-solid ratio, liquid specific gravity, solid specific gravity, solid granularity, rotation speed, paddle type, with or without baffle or internal coil. |

| Stirring blade Forms | Anchor type, frame type, flat paddle type, pitched paddle type, ribbon type, turbo type, pusher type and multiple compound type |

| Seal | Mechanical seal or stuff packing seal |

| Inner Surface Treatment | Polished or no polished |

| Discharge Valve | Flanged ball valve, open downward discharge valve and others |

| Technological Pipe Hole | Manhole, sight glass, distillation mouth, imported materials, pressure gauge port, temperature, mouth, mouth filling N2, |

*Mixing system for reactor

Mixing system is the core component of reactor, a cutom-made stirrer is your key to success. stirrer selection is related with the material's viscosity, liquid-solid ratio, proportion of liquid, solid's internal pipe coil etc.

*Main feature

Chemical Processing Machine: stainless steel chemical reaction vessel(reactor) is heated by the external coil or jacket to supply heat transfer conduction oil / steam / water, it is an ideal equipment of low power and high heating temperature and large volume.

A) Reduce the thickness of tank and increase its loading capacity.

B) Increase heat transfer efficiency.

C) Reduce power consumption and cost.

D) Reduce the total diameter of tank and be good for the layout of workshop.

*Specification of External half-pipe coil Reactor

| Type Item |

500L | 1000L | 1500L | 2000L | 3000L | 5000L | 8000L | 10000L | 15000L | 20000L | 25000L | 30000L | 35000L |

| Cylinder Size mm | 900×800 | 1100×1200 | 1300×1200 | 1400×15300 | 1600×1500 | 1800×2000 | 2100×22000 | 2200×2500 | 2600×2800 | 2800×3000 | 3000×3400 | 3200×3500 | 3200×4000 |

| Actual Capacity L | 699 | 1400 | 2166 | 3000 | 4066 | 6600 | 10038 | 12300 | 19456 | 24205 | 31084 | 36706 | 40725 |

| Outer Tube Size mm | Φ76/2 | Φ76/2 | Φ76/2 | Φ76/2 | Φ89/2 | Φ89/2 | Φ89/2 | Φ89/2 | Φ89/2 | Φ89/2 | Φ89/2 | Φ89/2 | Φ89/2 |

| Heating Area m2 | 1.7 | 2.6 | 3.8 | 4.5 | 5.8 | 7.5 | 11 | 13.2 | 18.6 | 21 | 26 | 30 | 33 |

| Inner Coil Size mm | Φ38 | Φ45 | Φ45 | Φ45 | Φ45 | Φ57 | Φ57 | Φ57 | Φ57 | Φ57 | Φ57 | Φ57 | Φ57 |

| Cooling Area m2 | 1.6 | 2.7 | 3.6 | 4.3 | 5.7 | 8 | 11 | 13 | 18 | 21 | 25 | 30 | 33 |

| Motor Power kw | 3 | 4 | 5.5 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 |

*Application of Resin plant:

Chemical Machine Resin Plant is the key equipment for producing all kinds of resins, such as Alkyd resin, Acrylic resin, PET resin, epoxy resins, ABS resins, Polyester resin, Unsaturated polyester resin, , Amino resin, curing agent.

The whole set of equipment includes reactor, vertical fractionating column, horizontal condenser, water storage tank, oil spill tank and piping (dilution kettle). All parts of the equipment that contact with the material are all made by stainless steel.

*Model selection reference of resin production equipment

| Composition | Instructions |

| Main Reactor | The size, material, heat transfer systems, mixing systems, sealing systems of reactor according to client's specification |

| Dosing Vessel | According to the client's demand, it adopts gravity tank, gravity mixing tank, gravity dispersing tank, gravity emulsifying tank. |

| Distillation Device | Vertical condenser, horizontal condenser and separator. |

| Vacuum system | All kinds of vacuum pumps, buffer tanks. |

| Thinning Vessel | The size, material, heat transfer systems, mixing systems, sealing systems of thinning vessel according to client's specification |

| Pipeline system | According to the client's demand, it decides the heating, cooling, vacuum and material pipelines, and including related valves, flowmeters and expanders etc. |

| Control System | According to client's demand, it decides manual, semi-automatic or full-automatic system. |

| Filter System | Frame filter, bag filter or centrifuge etc. |

| Operation Platform | Steel platform or concrete platform |

Polyester Resin Plants Manufacturer, Saturated Polyester Resin Plant, Un-saturated Polyester Resin Plant manufacturer, Alkyd Resin Plants, Polyester Resin Plants, PVA Emulsion Resin Plant, Epoxy Resin Plants

Products

- Polyester Resin Reactor

- ETO Sterilizer Machine

- Chemical Machinery & Equipment

- Pharmaceutical Equipment

- Paint Machinery

- Resin Manufacturing Plant & Machinery

- Ethylene Oxide Sterilizer

- ETO Sterilizer for Hospital

- Sigma Mixer Kneader

- Jacketed Reaction Vessel

- Cylindrical Autoclave

- Pvc Solvent Cement Adhesive Machine

- Eto Sterilizer Exporter in India

- Reaction Vessel Exporter in India

- sigma mixer manufacturer

- Drum Flaker