Agitator Stirrer mixer

Dispersing, Suspending, Emulsifying & Homogenizing Technik for Liquid and Paste

We design and manufacture a wide range of agitators for liquids and Paste for all process in the pharmaceutical, chemical, food, cosmetics and similar industries. Agitators are provided with different types of agitation components for process such as mixing, blending, dissolution, dispersion, homogenization, reaction, fermentation, oxidation, digestion and emulsification of liquid, paste, ointment, solution, viscous material and solid-liquid.

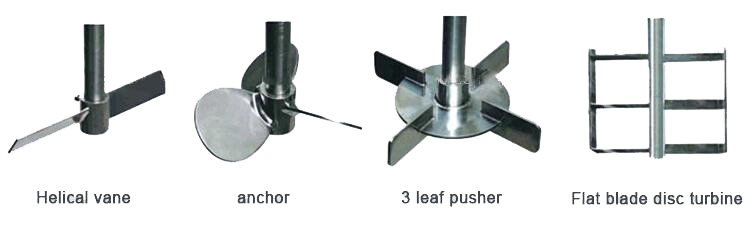

Agitators are designed and adapted to any vessel shape and can be implemented with or without lower support. Different types of blades can be combined depending on the process requirements. The sealing system are designed and adapted depending on the requirement of the various process and start from simple retainers to double mechanical seals. Agitators are available with different type of mounting as per suitability of the process and users requirements.

Specification fo Agitator

- Shape, diameter, sweep back angle and slant angle of the mixer blade.

- Number of layers and the vertical position of the mixer blade where it is installed.

- Rotating speed of the mixer blade

- Shape, inner volume, number of baffles and outline dimensions of the mixing tank

- Batch operation or continuous operation.

Agitators available with different type of drives and speeds with direct motor and with gear drive as per process requirements. Agitators are suitable for mixing volumes 5 liters to 10,000 liters.

Salient Features of Agitator:

- Design is cGMP - Current Good Manufacturing Practices compliance.

- All contact parts AISI 316 & non contact parts AISI 304.

- Capacity available for volume of 5 liters to 5,000 liters.

- Available various different type of mixing blade.

- Available different mounting of stirrer assembly.

1. Wall mounting.

2. Telescopic Stand.

3. Top of the vessels / Tanks.

4. Bottom of the Vessels / Tanks. - Can be provided Variable Speed Drive for stirrer by VFD.

- Option available for Explosion proof motor and controls panel.